Background

This was one of the first projects I made while figuring out the CNC machining process. With the help of some friends, I first learned how to operate the mill I would be using — a Series 1 Tormach PCNC 1100. After familiarizing myself with the basics — workholding, toolchanging, jogging axes, sending basic GCODE commands, etc. — I moved on to the CAD/CAM process.

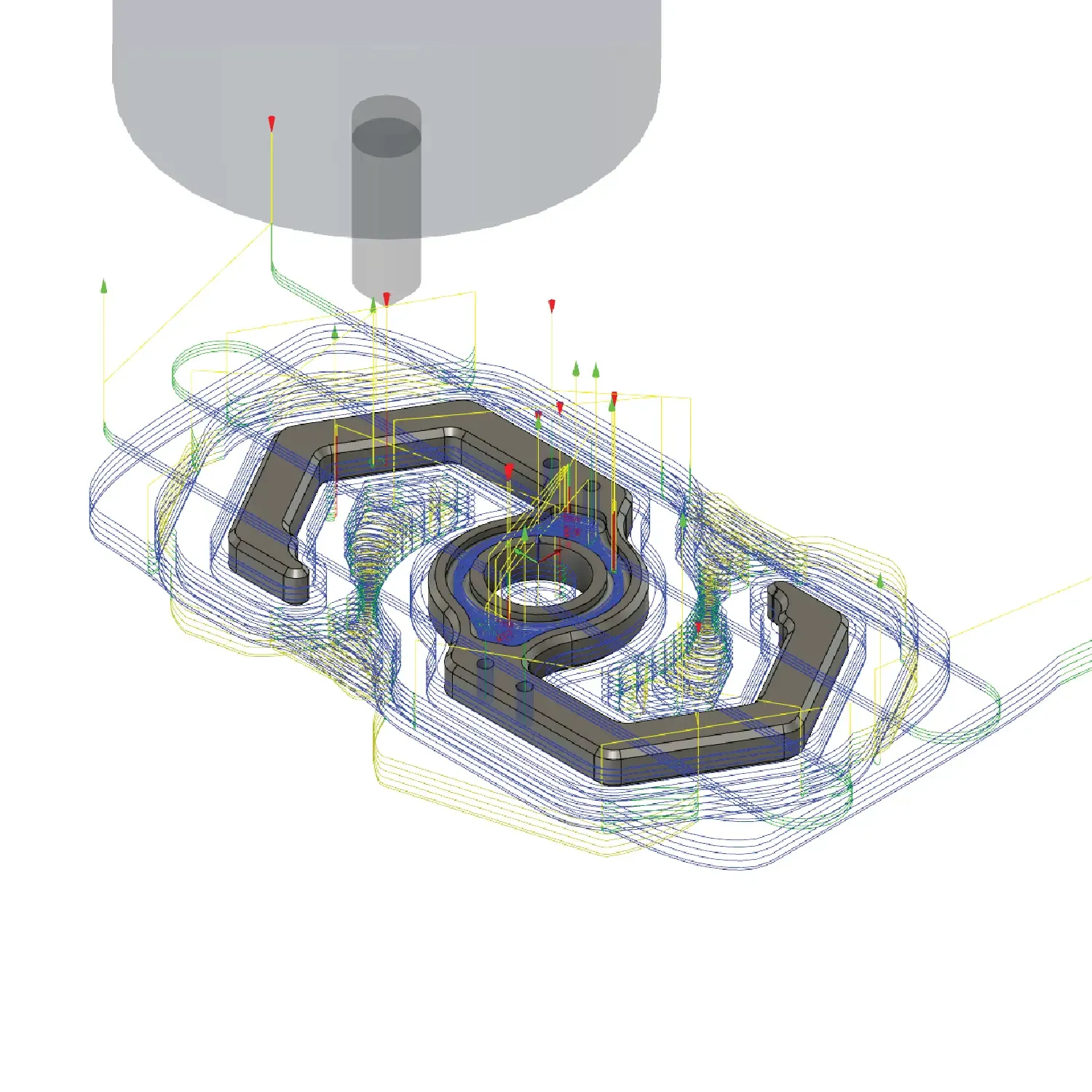

I designed the carabiner in Fusion 360 so that it could be machined mostly on one side, with just a chamfer operation on the opposite side. Here’s a rundown of the CAM operations I used:

| Operation |

|---|

| Face stock with 1/2” endmill |

| 2D adaptive clear with progressively smaller endmills, starting at 1/2” |

| Finishing contour with 1/8” endmill |

| 2D pocket with 1/16” ball endmill |

| Drill holes with 1/16” drill bit |

| Chamfer with 1/4” chamfer bit |

Conclusion

Overall I think the carabiner came out pretty nice. It definitely isn’t perfect, but I had fun making it and definitely learned a lot about CNC machining.