Background

For a little background information, The Tethering and Ranging Mission of the Georgia Institute of Technology (TARGIT) is a CubeSat Mission with the primary objective of demonstrating a LiDAR imaging system on a CubeSat platform. In order to test this imaging system, the satellite will deploy a small target with its own power system, electronics, communications equipment, and sensors, that will inflate a mylar balloon. This mylar balloon will serve as the target for the satellite’s imaging operations. You can read more about the project here.

Intro

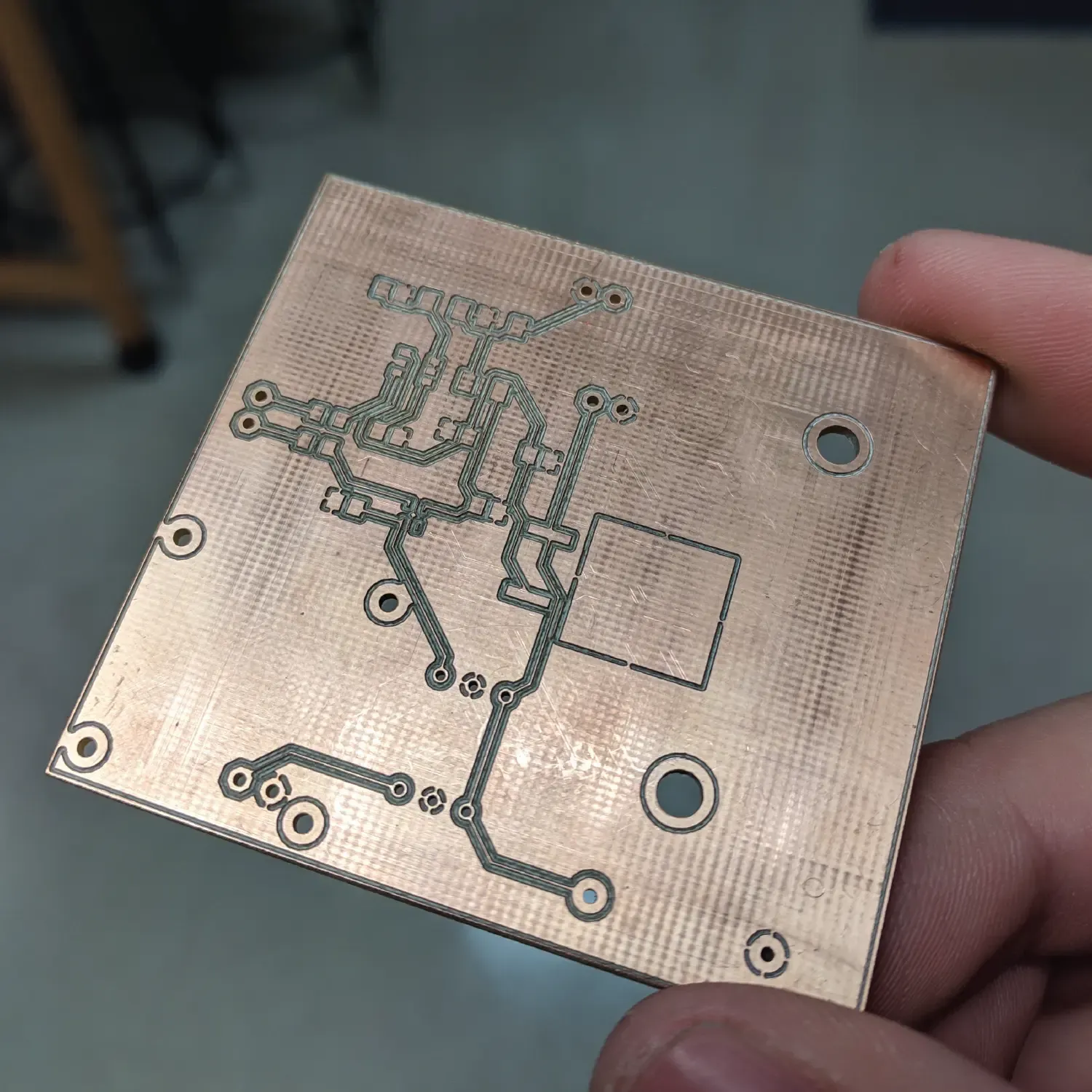

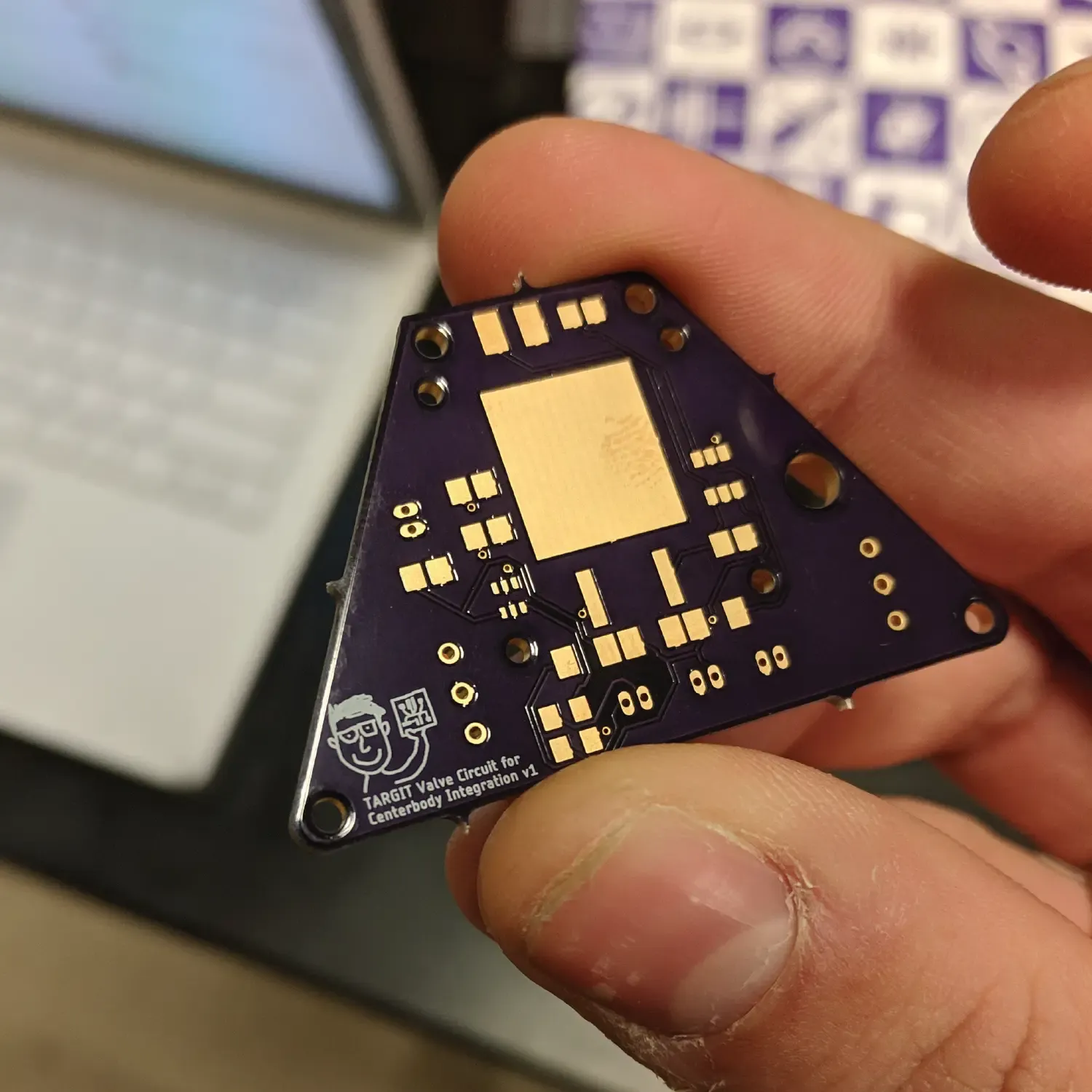

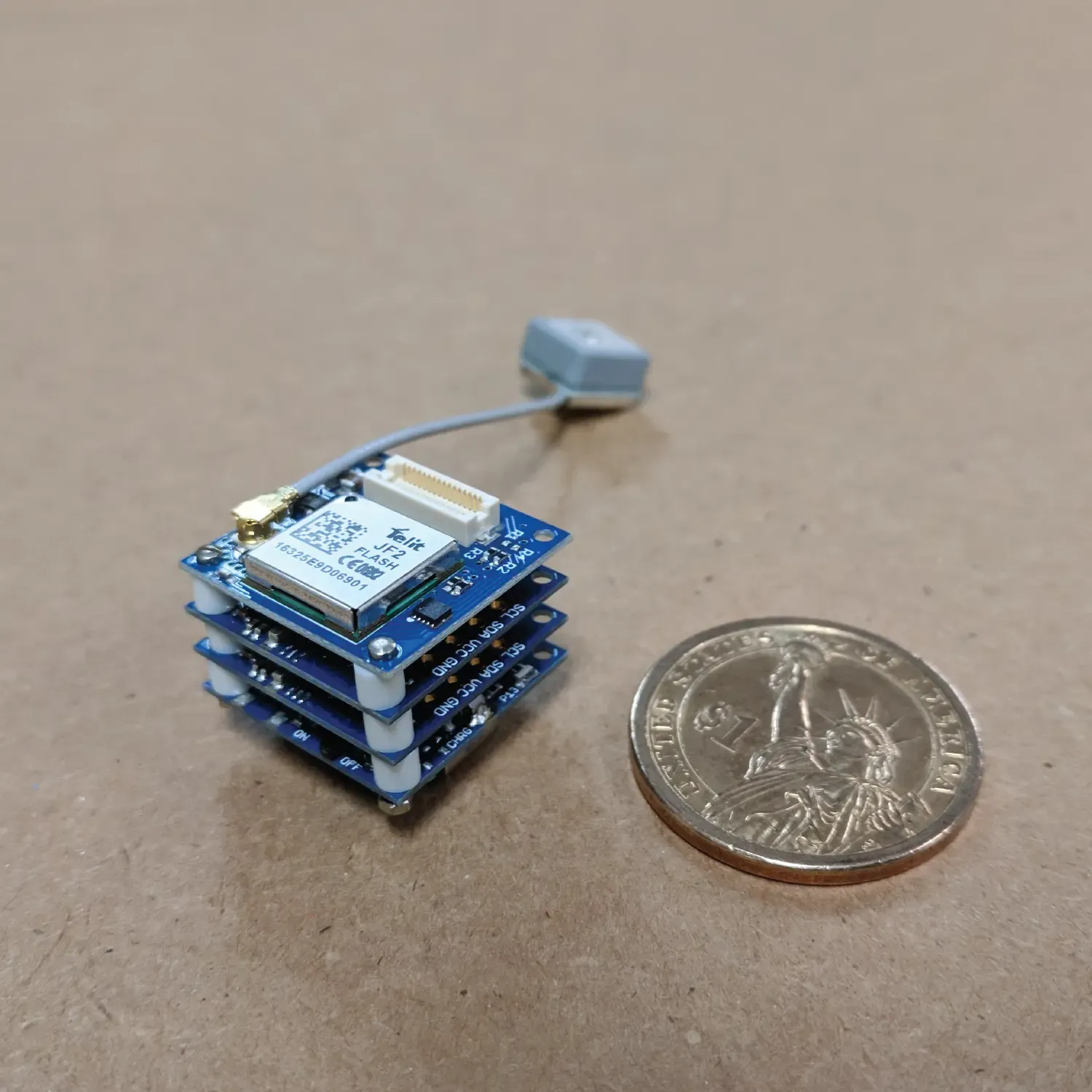

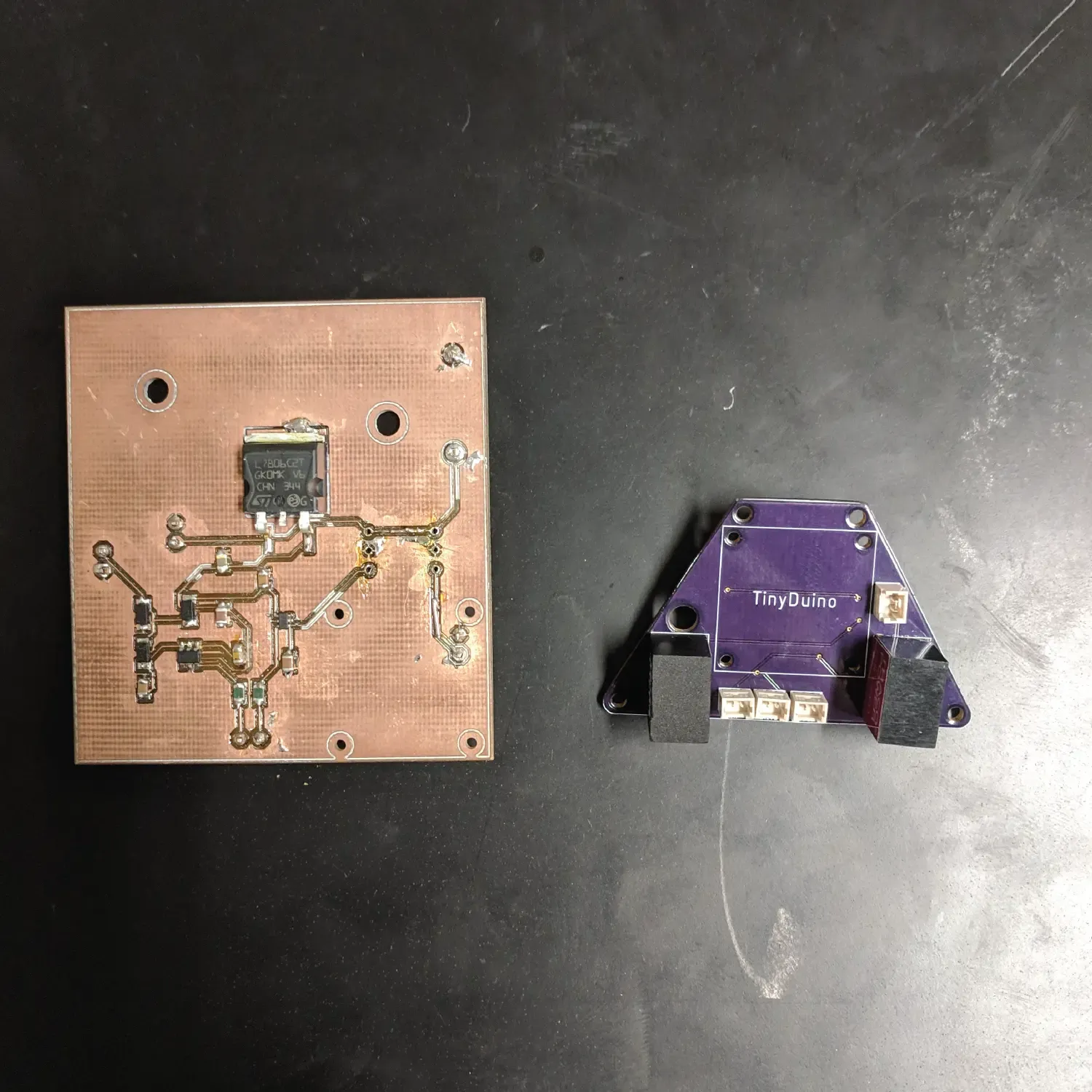

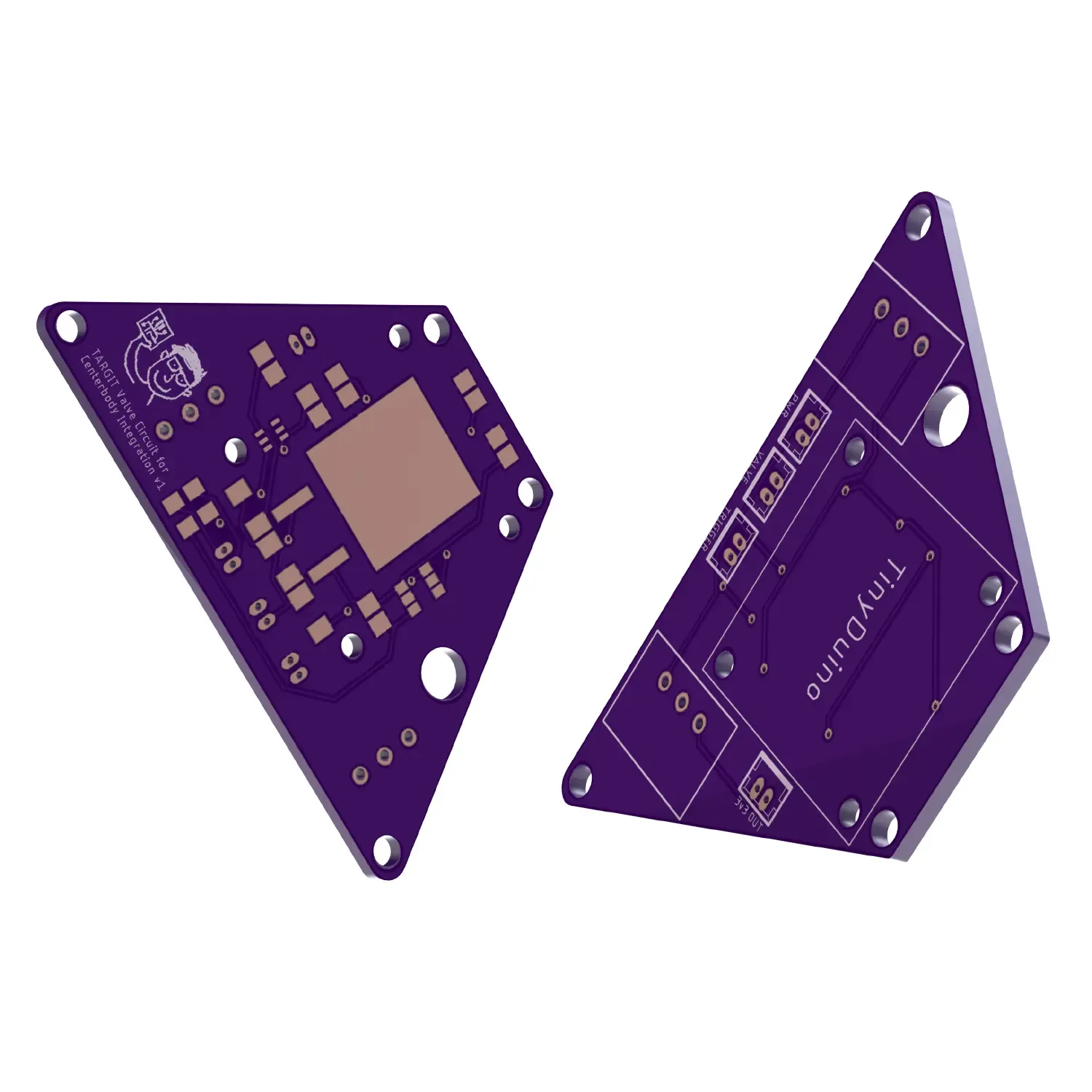

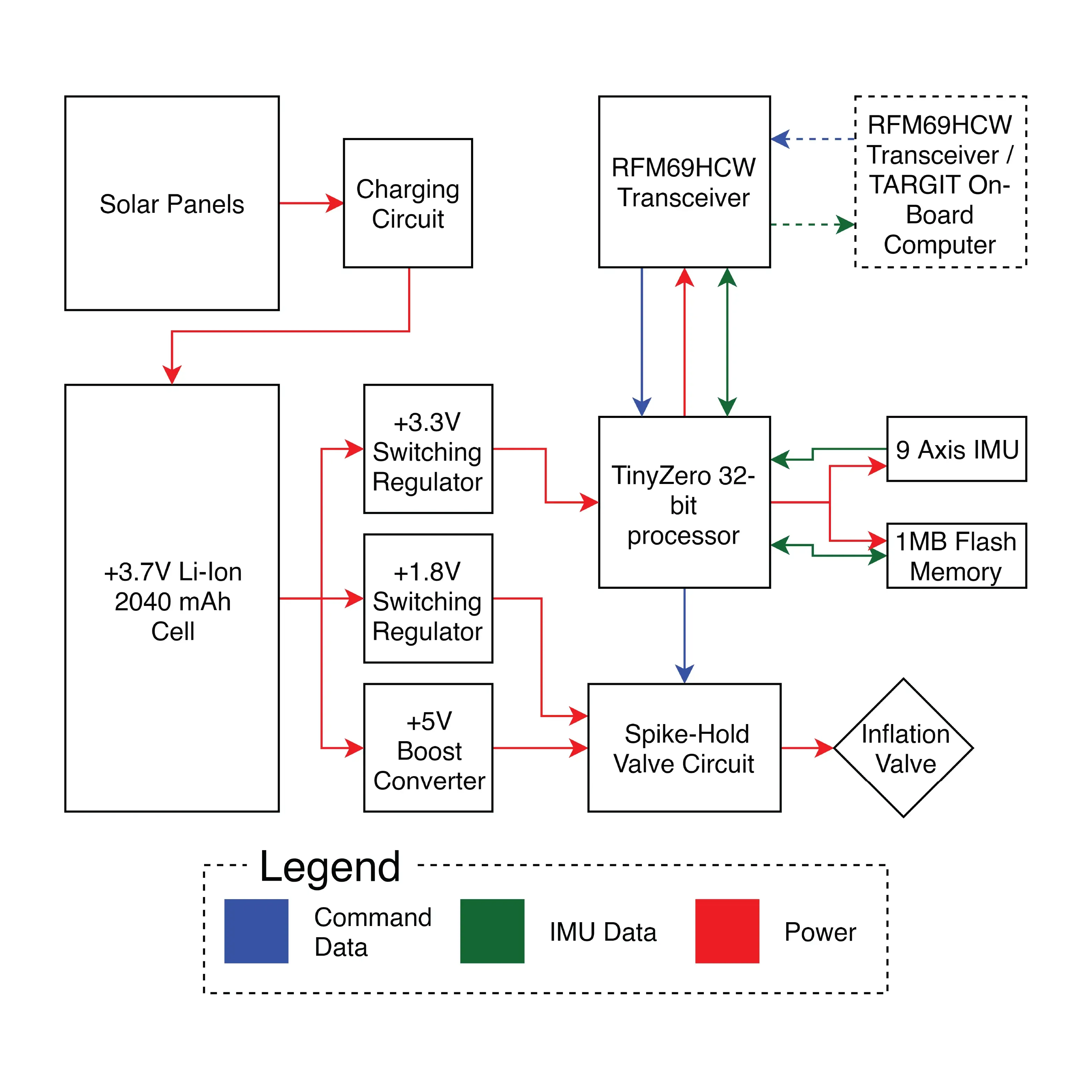

When I first started on the project in the fall of 2018, I worked on developing some of the electronics systems for the target subsystem. The system is centered around the TinyZero Microcontroller, which is basically just a tiny 32-bit Arduino-compatible microcontroller. I designed a motherboard for the TinyZero (Figure 1) that features power management/distribution features and a circuit that actuates solenoid valves to inflate the mylar balloon. I also designed a small shield for the TinyZero that allows it to interface with a radio transceiver. This radio transceiver is what communicates with the main satellite.

Prototyping

Over the course of two semesters, I learned how to use Autodesk EAGLE to design circuits and PCBs. I used on-campus resources, like the Mechanical Engineering Electronics Lab, to get single sided PCBs milled to prototype with. After validating my design, I moved on to a more compact two-sided design that was professionally manufactured via OSHPark. I sourced all the components for the board via DigiKey and assembled the board using a soldering iron. You can see the progression from prototype to completed board in the images below.